Practical 3D printing, one project at a time

I share the prints, ideas, and experiments that work in real homes. From small gifts to useful everyday tools, this is my workshop log.

What I am printing this week

I keep a rolling log of active prints on the A1, mostly because the machine never seems to sit idle for long. There is always something on the plate. Test pieces to prove out a new profile, calibration tools to validate filament, quick prototypes for household fixes and the odd experiment to see how far a material can be pushed. Keeping track of this stream of small projects gives a clear view of what is working, what needs adjustment and which ideas are worth developing further.

This log doubles as a practical record. If a profile starts drifting or a filament behaves differently from expected, I can look back at recent prints and spot the change. It also helps me compare new slicer features or patterns without relying on memory. Seeing a consistent trail of prints tells me more about a machine’s behaviour than any single benchmark test.

This week the focus is Christmas decorations. Some are for my home. Others are heading to family members who appreciate something made rather than bought. These are ideal prints for checking colour transitions, surface finish on detailed outer shells and overall profile stability. Their small size and short print time make them perfect for repetition, so they are a good way to keep the printer busy while gathering useful data.

Please have a look at my current projects for more details!

Recent prints from the workshop

A mix of functional home items, small gifts, and experiments. All printed on the A1 unless noted.

-

Christmas Ornament

This Christmas ornament by Sebo3D produces a detailed winter scene with a layered relief effect. It prints cleanly on an FDM printer

-

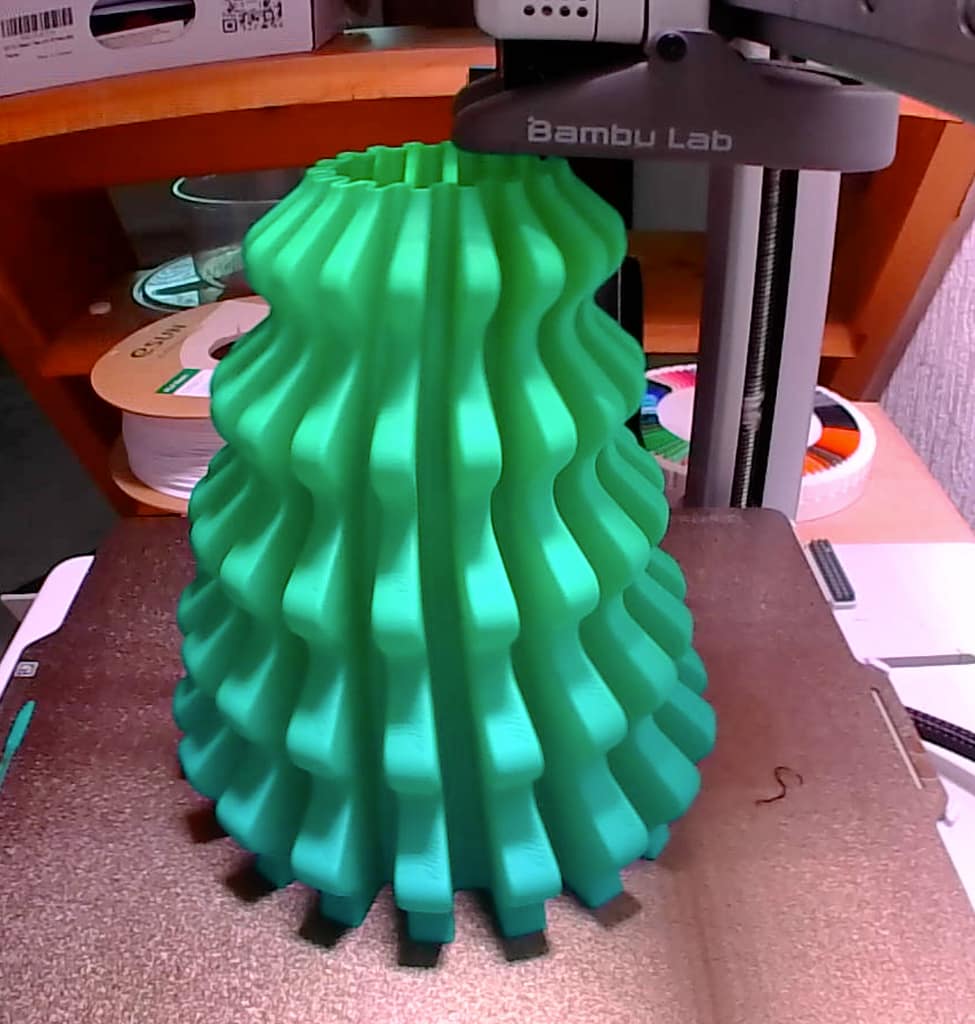

Christmas Tree Vase Mode Decoration

Overview I’ve been printing Christmas related items for the past 5-6 weeks but I wanted something else quick, giftable and

-

Uno Card Box – Snaplock

Overview This UNO snaplock storage box is a neat solution for keeping cards secure and protected. The model uses a

Materials I use every day

I print mostly in PLA and PETG. TPU when needed, and resin only when the job requires very fine detail. These notes come from practical use and real results, not datasheet theory.

PLA

Reliable, versatile, and ideal for most home prints. Easy to dial in and great for gifts.

PETG

Tougher and more temperature resistant. Useful for mechanical parts.

TPU

Flexible and fun. Ideal for bumpers, grips, and soft components.

Guides and workflow notes

Short walkthroughs based on real use. Settings that work, slicer approaches that help, and fixes that save time.

-

PETG as a Support Interface for PLA

1. Overview Using PETG as a support interface for PLA is one of the most powerful tricks in the Bambu

-

How to Choose the Right Infill for Functional Prints

Functional prints rely on more than just strong filament and good layer adhesion. Infill acts as the internal framework that

-

First Layer Troubleshooting

Overview The first layer is the foundation of every print. If it fails, the rest of the model will fail

About 3DBite

I started 3D printing more than fifteen years ago with a kit that needed constant tuning. Modern printers like the A1 make things far easier, but the engineering mindset still helps. 3DBite is where I share the projects, the materials, and the workflow that have worked for me.

Get updates and new print ideas

A short email once or twice a month with new projects, materials, and useful tips.

Add your newsletter form here.